We aim for total quality that focuses on your unique processes and requirements.

![]() M&M team is known for its ability to handle the most complex die-cast die projects, from single tools to multiple die programs. Innovative side actions and sub-core pull designs are our forte. We have the capacity and years of experience to design, build and deliver tooling that will streamline your manufacturing processes.

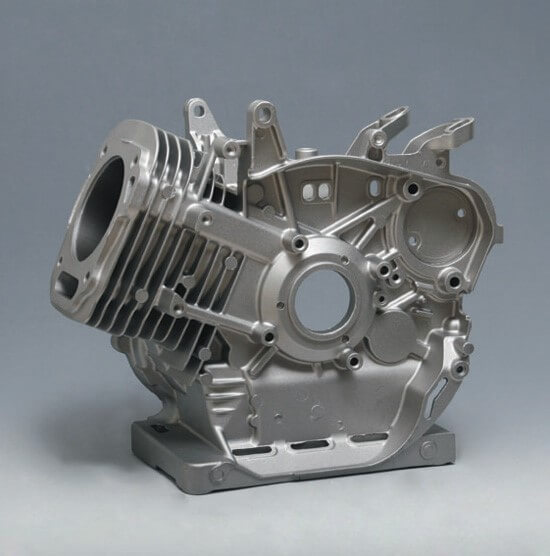

M&M team is known for its ability to handle the most complex die-cast die projects, from single tools to multiple die programs. Innovative side actions and sub-core pull designs are our forte. We have the capacity and years of experience to design, build and deliver tooling that will streamline your manufacturing processes.

We will incorporate your die standards and based on your production requirements, our engineering team will conceptualize and design your die to ensure that your finished tool functions at top efficiency with minimal waste and downtime. All components are precisely built and assembled with durability, efficiency and interchangeability in mind.

Quality materials MATTER. So our experts carefully review steel certifications to insure they fall well within the specifications you require us to follow. Only the best-known name brands are used for your dies. Another advantage: our steel and heat-treat suppliers are located within miles of our facility, so when you need a replacement component expedited, we can respond quickly to get you up and running again.

A quality die is crucial to making a good casting, but service and trust are equally important.

![]() Whether it means attending a die sampling, handling an emergency repair, troubleshooting existing or inherited tooling, or simply consulting with you on an upcoming project, we are ready when you need us.

Whether it means attending a die sampling, handling an emergency repair, troubleshooting existing or inherited tooling, or simply consulting with you on an upcoming project, we are ready when you need us.

Longtime customers trust us to handle their most time-sensitive and confidential projects. We will take all necessary steps to safeguard your intellectual property and deliver the total quality you need.